Cold weather brings unique challenges for those who rely on vehicles for their livelihood or lifestyle.

From truckers hauling goods across state lines to families enjoying a winter getaway in their RV, the risk of frozen pipes and components is a serious concern.

A sudden drop in temperature can lead to costly damage and significant downtime.

This is where heat trace technology becomes an essential solution, offering robust transportation freeze protection and ensuring travel reliability when it matters most.

This article explores the application of heat trace systems, particularly self regulating heat trace, in the transportation and RV sectors.

We’ll cover how this technology works, its key benefits, and specific applications that keep vehicles and their systems functioning smoothly, even in the harshest winter conditions.

Understanding these solutions can help prevent unexpected interruptions and maintain the integrity of your mobile assets.

The Challenge of Cold Weather on the Road

Extreme cold can wreak havoc on vehicles, especially those with complex fluid systems. When temperatures plummet, the consequences can be severe and wide-ranging.

Risks for Commercial Transportation

For the trucking and transport industry, time is money. Frozen systems can lead to:

- Fuel Gelling: Diesel fuel can thicken and turn into a waxy solid, clogging fuel lines and filters and preventing the engine from running.

- Frozen Fluid Lines: Water, DEF (Diesel Exhaust Fluid), and hydraulic lines can freeze and burst, causing leaks and system failures.

- Damaged Equipment: Ice expansion can damage pumps, valves, and tanks, leading to expensive repairs and extended vehicle downtime.

Issues for RV Owners

Recreational vehicles face similar threats, which can ruin a trip and result in costly repairs. Key problems include:

- Frozen Water Systems: Fresh water, gray water, and black water tanks and pipes are all susceptible to freezing. This can lead to burst pipes, a lack of running water, and unsanitary conditions.

- Propane Flow Interruption: In extremely cold temperatures, propane pressure can drop, affecting the performance of heaters, refrigerators, and stoves.

- Safety Hazards: Frozen steps and entryways can become slippery, increasing the risk of slips and falls.

Understanding Heat Trace Technology

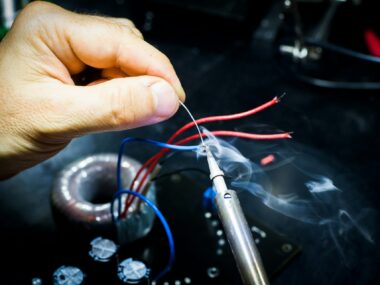

Heat trace, also known as heat tape or heating cable, is a system used to maintain or raise the temperature of pipes and vessels.

It is an electrical solution designed to prevent freezing by applying consistent, controlled heat directly where it’s needed.

Components of a Heat Trace System

A typical heat trace system includes several key parts:

- Heating Cable: This is the core component that generates heat.

- Thermostat/Controller: This device regulates the temperature, turning the cable on and off to maintain a set temperature and conserve energy.

- Insulation: Thermal insulation is applied over the heating cable and pipe to minimize heat loss and maximize efficiency.

- Power Connection Kit: This connects the heating cable to the power source.

Types of Heating Cables

There are different types of heating cables, but the most advanced and widely used for these applications is self-regulating heat trace.

Unlike constant wattage cables that produce the same heat output regardless of temperature, self-regulating cables are much smarter.

They have a special conductive core that automatically adjusts its heat output along its entire length based on the surrounding ambient temperature. This means it provides more heat in colder spots and less in warmer spots, making it safer and more energy-efficient.

Benefits of Self-Regulating Heat Trace

Using a self-regulating heat trace system offers significant advantages for both commercial transportation and RV heating. Its intelligent design addresses many of the challenges posed by cold weather.

Safety and Efficiency

- Prevents Overheating: The self-regulating nature of the cable means it won’t overheat, even if it’s overlapped. This makes it safer to install and operate compared to other heating cable types.

- Energy Savings: By adjusting heat output based on need, the system consumes less power, leading to lower energy costs.

Durability and Reliability

- Long Lifespan: These cables are built to withstand harsh conditions, including exposure to chemicals, moisture, and physical impact.

- Consistent Performance: It provides reliable freeze protection, ensuring that critical systems remain operational and preventing costly downtime.

Ease of Installation

- Flexibility: The cable can be cut to the exact length required on-site, simplifying the installation process and reducing waste.

- Versatility: It can be installed on various types of pipes and tanks, made from both metal and plastic.

Heat Trace Applications in Transportation

In the commercial transportation industry, maintaining operational readiness is paramount. Heat trace systems are applied to several critical areas to ensure vehicles keep moving.

Fuel Systems

To prevent diesel fuel gelling, heat trace can be applied to:

- Fuel tanks

- Fuel lines

- Fuel filters

This ensures a steady flow of fuel to the engine, regardless of the outside temperature.

Fluid and Air Lines

Other essential systems that benefit from freeze protection include:

- DEF Systems: Prevents DEF from freezing, which can halt engine operation in modern diesel trucks.

- Air Brake Lines: Keeps moisture in air lines from freezing and causing brake system failure.

- Hydraulic Lines: Maintains fluid viscosity for the reliable operation of hydraulic equipment like liftgates.

Enhancing RVs with Heat Trace Solutions

For RV enthusiasts, heat trace is a game-changer for winter travel, transforming the vehicle into a true four-season home on wheels.

Comprehensive Water System Protection

The primary application for RV heating is the water system. Heat trace can be installed on:

- Fresh Water Hoses and Tanks: Ensures a continuous supply of drinking and washing water.

- Gray and Black Water Tanks: Prevents waste from freezing, allowing for proper disposal.

- Drain Pipes and Valves: Keeps drain lines clear and functional.

Additional RV Applications

Beyond water systems, heat trace adds comfort and safety in other ways:

- Heated Steps: Applying heat trace to metal entry steps prevents ice buildup, reducing the risk of accidents.

- Pipe Protection in Bays: Protects pipes running through unheated storage compartments, a common weak spot in RV winterization.

Your Partner in Transportation Freeze Protection

Whether you’re managing a fleet of commercial trucks or preparing your RV for a winter adventure, protecting your assets from the cold is essential.

Heat trace technology offers a reliable, efficient, and safe solution to prevent freezing, minimize downtime, and ensure peace of mind on the road. By investing in a quality system like self-regulating heat trace, you can confidently face cold weather, knowing your vehicle’s critical systems are secure.

If you are looking for solutions to enhance your travel reliability during the colder months, exploring heat trace options is a logical next step. Contact a specialist to discuss your specific needs and find the right products to keep you moving all winter long.